One of the most common defects found by fire door inspectors is that the door leaf has been over-trimmed.

Many fire door installers are unaware of the limits that apply to the trimming of fire doors at their edges, and seem to think fire doors are solid throughout and can therefore be cut down and reduced in size to fit the door frame opening.

Only certain fire doors can be cut

Let’s be clear – only fire door blanks that are designed to be fabricated by a competent person to produce custom made fire doors, according to the standard UK door sizes, can be cut to size. In these cases, the technical manual for the door blank will state how this can be done whilst maintaining fire performance certification.

There are very few other fire doors that can be trimmed by more than just a few millimetres.

Why fire door installers must be vigilant

Fire door installers should understand what limits apply to different types of fire doors before they trim the edges when installing fire doors in buildings.

If they trim too much from the edge of the door, the fire resistance performance certification will be void and the door may fail to perform adequately in a fire. The door frame should always be made to suit the door leaf dimensions and to suit the opening in the compartment wall.

Why not trim?

Many types of fire doors have hardwood lipping fixed to their edges, timber framing behind that lipping, and a particleboard core within that framing, which should also include approved intumescent strips. If you trim by too much and reduce the size of the lipping or framing, or indeed worse still expose the core, then the door’s fire resistance performance could well be adversely affected, and the fire performance certification will no longer apply.

Clearly, this could leave the building operator without suitable fire protection within commercial spaces and increase the likelihood of fire spreading out of control within the building.

A fire door installer who trims or cuts a fire door beyond the specific allowance could find themselves in trouble and subject to claims and prosecutions from those persons and organisations affected.

Make the frame fit the door – do not cut standard fire doors to size.

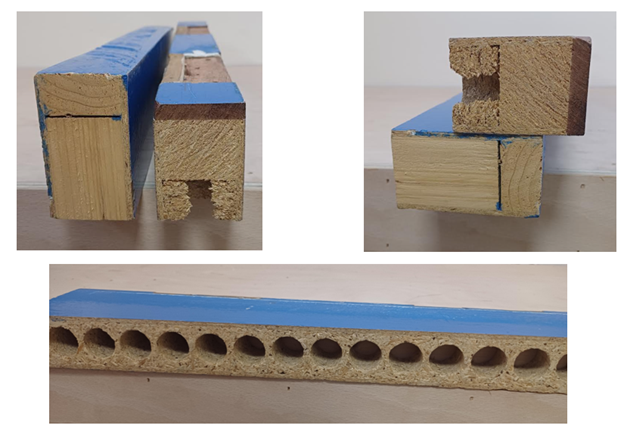

Visual evidence of over-trimming

These images show an over trimmed edge of a fire door compared with an untrimmed edge. You can see how much weaker the trimmed edge could be, potentially compromising the door’s effectiveness in providing up to 60 minutes of fireproof protection. Also shown is an image of a ‘Tubeboard’ fire door particleboard core, normally protected by the timber framing around it and the hardwood lipped edges of the door.

Survey before installation

If you are asked to fit a new fire door into an existing door frame, carry out a full survey to make sure this installation can include the appropriate batwing while maintaining the fire resistance performance certification for the door.

It is far better to fit a complete new fire door assembly or fire door set. Compliance matters very much when it comes to fire safety.

Understanding door sizes and specifications for fire safety

Whether you’re working with internal doors or external doors, understanding fire door sizes and core features specifications is essential to ensure compliance and performance in the event of a fire. Fire doors are manufactured in set door sizes, all of which must be carefully matched to the required opening width.

Installing a fire door that doesn’t meet the correct width or height specifications could compromise its fire rating and allow the spread of fire through the building. Always choose doors from our versatile collection that are tested and certified in accordance with relevant standards to provide peace of mind. If you’re unsure about what size or type of fire door to use, seek further information or expert advice before installation. This ensures not only compliance but also safety for building occupants.

Need help?

Contact us via www.firedoorscomplete.com for assistance with your fire door installation and remediation projects. Don’t take risks – if you don’t know, you can always ask.

Frequently Asked Questions

What are the standard fire door sizes available in the UK?

The main difference in the standard fire door sizes available in the UK typically includes 1981mm x 838mm (33 inches x 78 inches) and 1981mm x 762mm (30 inches x 78 inches) for internal doors.

How do I measure for a single door fire door to ensure the correct fit?

To measure for a fire door, you should measure the height and width of the existing door frame, ensuring to account for any irregularities or obstructions.

What is the difference between FD30 and FD60 fire doors regarding size, rating, and acoustic seals?

FD30 fire doors provide 30 minutes of fire resistance, while FD60 fire doors offer 60 minutes. The sizes can be similar, but the construction and materials differ to meet the required fire ratings.

Where are smaller or larger fire doors typically installed to enhance customer experience?

Smaller fire doors are often installed in residential settings, while larger fire doors are usually found in commercial properties or areas requiring higher fire resistance.

What metric and imperial sizes are common for internal fire doors according to the standard UK requirements?

Common metric sizes for internal fire doors include 1981mm x 838mm and 1981mm x 762mm, while imperial sizes include 33 inches x 78 inches and 30 inches x 78 inches.

Do fire rated door frames need to match the fire door size exactly for a custom quote?

Yes, fire rated door frames should match the fire door size closely to ensure proper installation and maintain the fire integrity of the door assembly.

Are there specific fire door sizes required for residential versus commercial buildings, particularly considering an increased door thickness?

Yes, residential buildings may have different fire door size requirements compared to commercial buildings, often influenced by building regulations and fire safety standards specific to each type of occupancy.